PUF Panel Roof Sheet

We offer wide range of PUF Insulated Panels for the various applications such as Cold Storages, Pack Houses, CA chambers, Banana Ripening Chambers, Freezer Rooms, any type of industrial application for Roofing, Wall Cladding, Partitions, Walk On Ceilings, Prefabricated Shelters, Accommodation Shelters, Information Kiosks, Health Centres, Community Shelters, Communication Shelters, High Altitude Accommodation Shelters for Sub Zero Temperature Areas and many more.

These PUF panels are manufactured in a computerised plant and come with Pre-Painted Galvanized Steel Sheets (PPGS), Pre Painted Galvalume Steel Sheets, and Stainless Steel Sheets fascias. The density of Poly Urethane Foam (PUF) sandwiched between two fascias is 40 + 2 Kg/ M3.

We offer the range of thickness of panels as follows with various fascia options:

Wall Panels: 40 mm, 50 mm, 60 mm, 80 mm, 100 mm, 120 mm, 150 mm.

Roof Panels: 30 mm, 40 mm, 50 mm, 60 mm, 80 mm, 100 mm, 120 mm, 150 mm.

Jalaram Industries sandwich panel consists of two facings of relatively thin metal sheets. To suit roofing needs, the core is of appropriate strength but is still light weight. It has sufficient stiffness in a direction normal to face of the panel. The core is made of durable polyurethane. The facings are of steel or aluminium, making the roofing durable. Jalaram Industries sandwich panel sheets are available thickness ranging from 30 to 120 mm. They are available in widths of 1000 mm to 1200 mm. The maximum length of each panel is 15 metre.

Because of its construction, Bhagawaati Royal Roof sandwich panel sheets have an inherent advantage over normal panels used for roofing. They include:

- High load bearing capacity at low weight

- Excellent and durable thermal insulation

- Absolute water and vapour barrier

- Excellent air tightness and free of thermal bridges which results in considerable energy savings.

- Surface finished facings providing resistance to weather and aggressive environments

- Capacity for rapid erection without lifting equipments; easier installation in hostile weather conditions

- Easy repair and replacement in case of damage

- Long life and very low maintenance cost

- Good sound insulation

- Reasonable fire reaction and resistance

Features

- Modular in nature and pre-engineered for precision and simplified construction

- Options available with various finishes like PPGS / PPGS, PPGL / PPGL, PPGS / SS

- Walls of different height, yet sturdy and strong construction

- Light weight panels which is easy to lift and erect at any height inside the plant or any other place

- Frameless construction and ease of design, supply and erect for any types of construction

- Insulated Panels and saves the energy

Best-in-class PUF panel features

- Improved thermal and acoustic insulation

- Energy savings for enormous economic benefits

- Offered in endless dimensional requirements

- Lifetime durability and high load bearing capacity

- Premier water and vapor resistance

- Flexible design options

- Easy installation and low maintenance requirements

- Ready to use and aesthetically pleasing PUF sheet roofing

- Used as Structural Insulation Panel (SIP) eliminating the need of masonry

- Lifetime weatherproof guarantee

- Supreme flame retardation with self extinguishing property

- Polyurethane foam insulation panels are 100% environment friendly

- Resistant to corrosion, termites, physical impact and fungus

The perfect envelop for multiple applications

Thermal efficiency, lifetime durability and fire resistance are characteristic features of sandwich PUF panels manufactured at EPACK. A wide range of applications across multiple industrial and commercial platforms has empowered organizations to lead their respective sectors.

The flexibility of polyurethane insulation panels has been the main force behind:

- Food processing industry

- Cold storages

- Clean Rooms

- Telecom Shelters

- Fruit & vegetable storage

- Milk & dairy industry

- Floriculture industry

- Prefab buildings

- Warehouses

- Ripening chambers

- Seafood industry

- Meat & poultry industry

- Pharmaceutical storage

Benefits from EPACK

The life, efficiency and hygiene of any structure depends upon the panels that go into its making. The prefabricated PUF panels manufactured by EPACK offer high performance and low energy consumption. Having a team of expert structural engineers, designers and Draughtsman, every product manufactured reflects the organization’s ethos of quality, precision and efficiency.

Our products undergo extensive testing before Rollout. These tests are performed in accordance with highest industry norms at our state-of-the-art manufacturing facility.

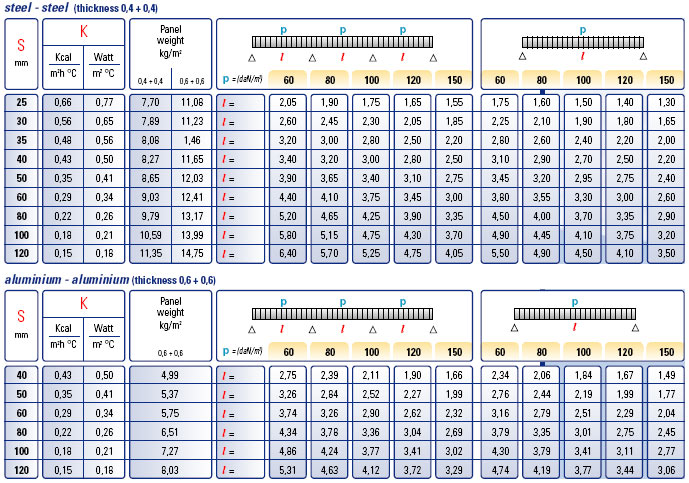

Table Of Safe Spans

Jalaram Industries guarantees the values of the external face in steel, 0.5 mm thick, and internal face in steel, 0.4 mm thick or with both faces in aluminium 0.6 thick with external face in aluminium, 0.6 mm thick, and internal face in steel, 0.5 mm thick. The spans per metre as a function of a uniformly distributed overload P (kgf / m2) have been obtained from load tests carried out in Jalaram Industries laboratories, and provide a deflection f <= l / 200 with a safety coefficient that complies with the UEAtc standards for insulated panels, which have been established and are implemented by primary European Certifying Organizations.

With external and / or internal steel thickness inferior to the above mentioned ones, the guarantee on the admissible loads for the spans indicated in the table is maintained, while it is not maintained on the deflection limit and the safety coefficient.

Jalaram Industries has many sandwich panel roofing sheet profiles. At Mamata, we are their stockists for the Glamet roofing panel and the Mono roofing panel.

Jalaram Industries Glamet Sandiwch Panels

These CFC free traditional roofing sheets use self supporting polyurethane insulation material for pitched roof. While it is meant to work for slopes of 7% or more, it is possible to use Jalaram Industries Glamet for slopes less than 7% with expert technical advice.

Jalaram Industries Glamet sandwich panels use a high tensile base metal which is coated with Zinc and Aluminium ally. This makes the roofing sheets durable. In addition, the exterior side of the panels is coated with a micro layer of polyster primer. This makes Jalaram Industries Glamet resistant to water absorption. The PUF core gives it high thermal resistance.

Jalaram Industries Monoroof Centesimal

Just like Glamet, the Jalaram Industries Monoroof Centesimal too is considered a traditional roof. It has an external steel face and an internal face made of centesimal aluminium. Sandwiched between these two panels is sturdy self supporting polyurethane. These pitched roofs need a minimum slope of 7%, but it can be used for lesser slopes as well – with the advice of an expert technical person. The side of the panel has a surface finish manufactured from aluminium foil that has a thickness of 0.08 mm.

| Width-wall | 1200mm (Standard/Customized) | |||||||

| Width roof | 993mm | |||||||

| Core Thickness | 30 | 40 | 50 | 60 | 80 | 100 | 120 | 150 |

| K value (W/m2 .K) | 0.75 | 0.53 | 0.43 | 0.33 | 0.28 | 0.22 | 0.18 | 0.15 |

| R value (Btu/hr/ft2/.F) | 9.8 | 11 | 13 | 16 | 20 | 26 | 30 | 38 |

| Fascia Options | PPGS/PPGL/Alu/Tarfelt/Cement Fiber Board/SS | |||||||

| Thermal Conductivity at 10.C mean Temparature (w/m3k) | 0.023 | |||||||

| Compressive Strength at 10% Deformation (Kg/cm2) | 2.1 | |||||||

| Bending Strength (Kg/cm2) | 4 | |||||||

| Tensile Strength (Kg/cm2) | 3.7 | |||||||

| Adhesive Strength (Kg/cm2) - foam to steel | 2.9 | |||||||

| Water Absorption (Volume %) | 0.2% at 100%RH | |||||||

| Closed Cell Content (%) | 92-95% | |||||||

| Vapor Permeability at 90% (RH) & 38 .C (Gms/Hr.m2) | 0.12 | |||||||

| Fire Class | Fire Resistant | |||||||